Slag processing

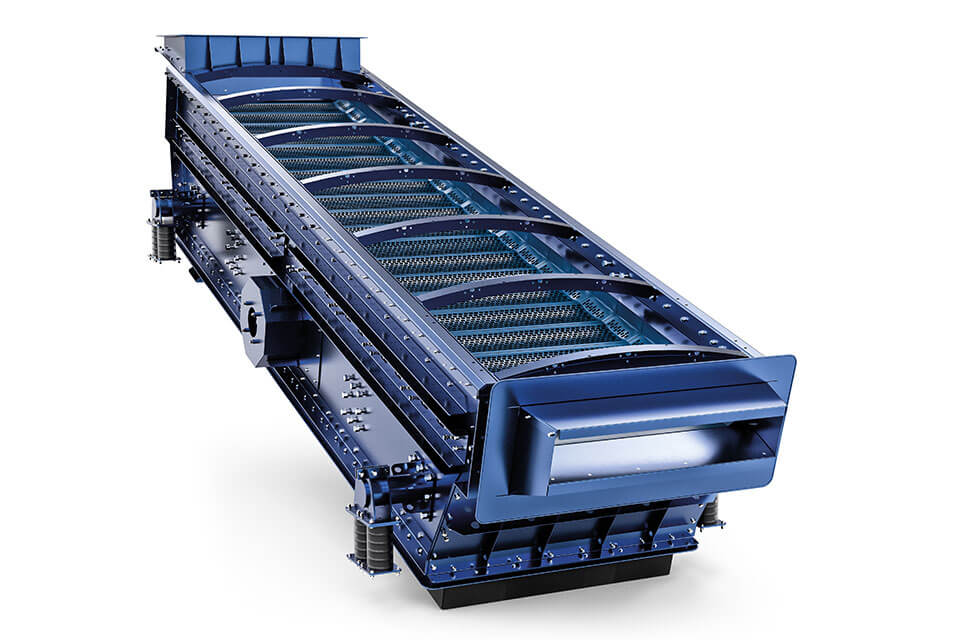

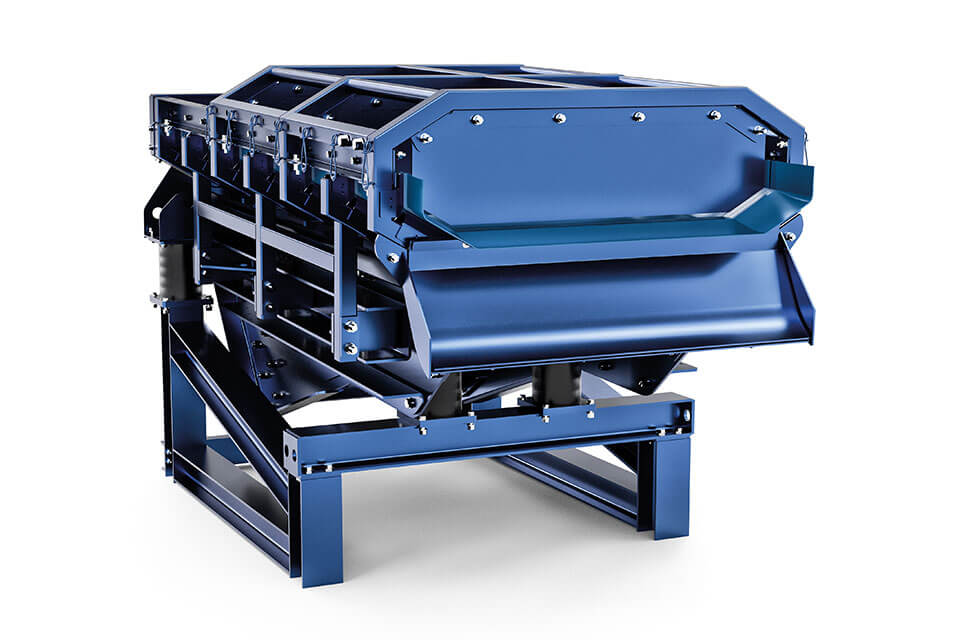

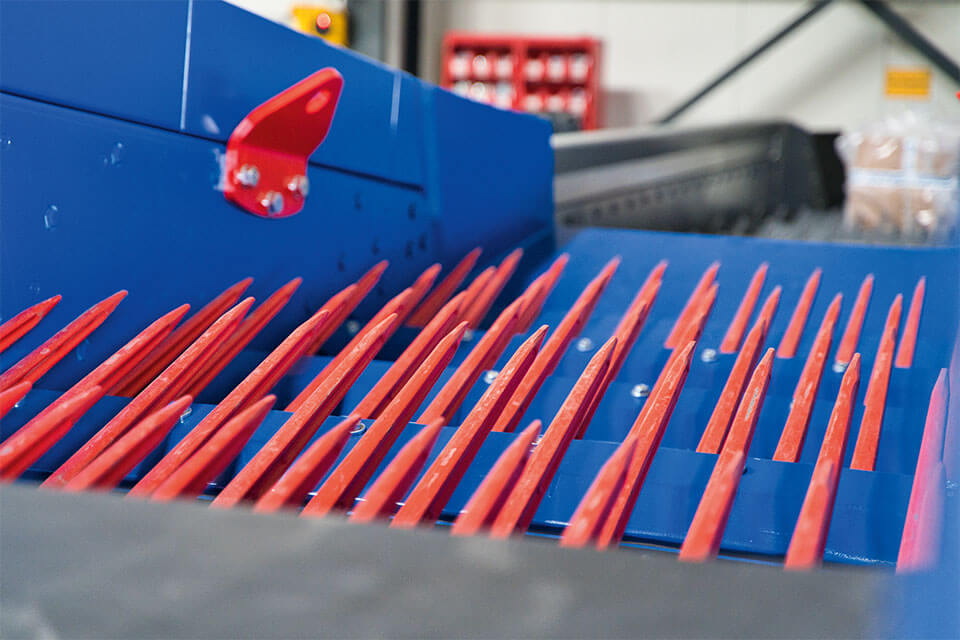

As the world’s leading manufacturer of screening machines, we offer the best screening results for processing steel mill slag, ash from waste incinerators, waste incineration plant ash, such as incinerator bottom ash (IBA) and fluidized bed ash, and many more…