GMP for screening machines & vibratory feeders

The requirements and regulations of Good Manufacturing Practice not only affect production companies in the pharmaceutical, chemical & food industry, but are also directed at manufacturers of production plants. As a manufacturer of stainless steel screening machines and stainless steel vibratory feeders, we at SPALECK manufacture according to GMP and other relevant standards. Thus, the SPALECK GMP screening machines and GMP vibratory feeders are optimally integrated into your manufacturing process.

Depending on customer requirements, we offer special design features for the intended use. These include, among others

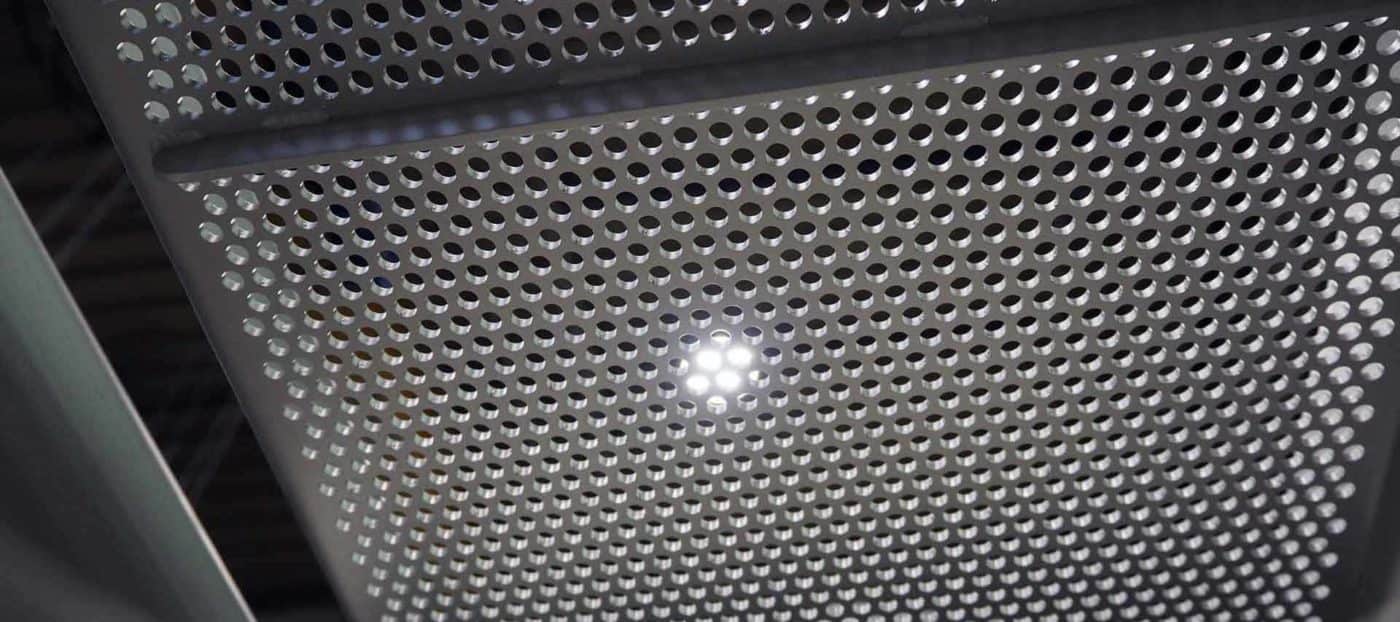

- polished surfaces with minimal surface roughness (up to Ra < 0.2 µm)

- rounded edges and welds to avoid dead zones

- a CIP cleaning by means of integrated nozzle systems

GMP in the production of medicinal products

Screening, dosing & conveying in the production of medicinal products

Good manufacturing practice (GMP) is particularly present in the field of medicines, drugs and active medical ingredients in order to guarantee patients a consistently high quality of medicines and active ingredients. In order to maintain and improve the health of many people, Good Manufacturing Practice describes measures to ensure the efficacy and safety of medicinal products. These measures for the quality assurance of medicinal products include the entire production processes & production environments. Here, our pharmaceutical screening machines and pharmaceutical vibratory feeders are ideal production facilities.

GMP in the food industry

Conveying and screening technology in food production

In addition, GMP covers not only the area of pharmaceuticals, but also other industries, such as the food and feed industries. The aim of Good Manufacturing Practice is always to produce safe and harmless products of uncompromisingly high quality. Industries for which we produce stainless steel screening machines and stainless steel vibratory feeders according to GMP standards include:

- Chemistry

- Cosmetics

- Medical devices

- Food

- Pet food

What does GMP mean?

GMP is the abbreviation for “Good Manufacturing Practice”. The rules of GMP are laid down in national and international regulations to guarantee binding standards. GMP is intended to ensure high quality throughout the entire manufacturing process of products. This applies, for example, to the production, processing, packaging and storage of medicines, foodstuffs, pet food or chemical products. Above all, there are strict requirements for hygiene, equipment, premises and controls (documentation) in the manufacturing process.